Makkah Group

Technology & Solution

Technology & Solution

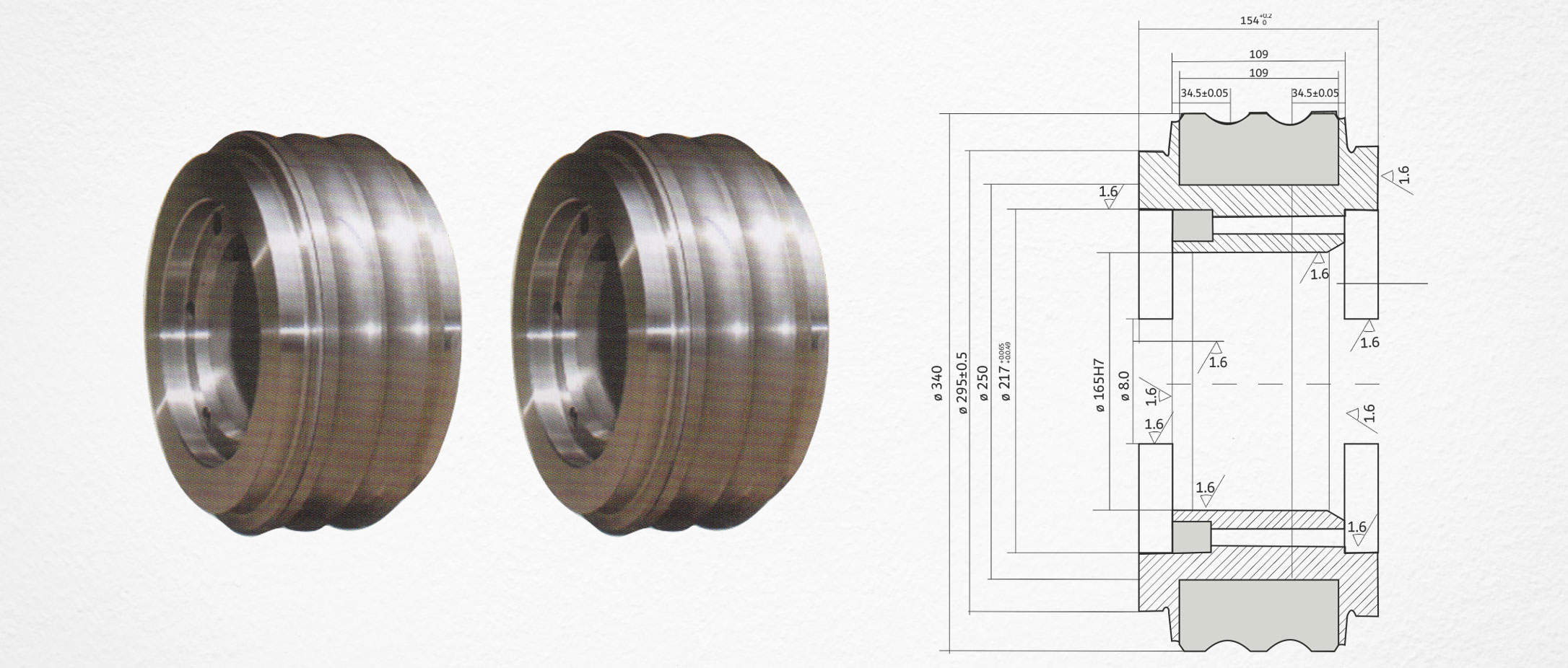

| External Diameter (mm) | Inner Diameter (mm) | Height (mm) |

|---|---|---|

| 100 - 500 | 50 - 380 | 20 - 250 |

| Designation of Rolls | External Diameter ≤200mm | External Diameter ≤200mm | |||

|---|---|---|---|---|---|

| Better | Ordinary | Better | Ordinary | ||

| Out diameter | ± 0.02 | ± 0.05 | ± 0.03 | ± 0.05 | Special Requirements |

| Inner diameter | ± 0.02 | ± 0.025 | ± 0.035 | ± 0.055 | |

| Height | 0 | 0 | 0 | 0 | |

| ± 0.025 | ± 0.05 | ± 0.05 | ± 0.05 | ||

Note: we can supply them according to the drawings provided by customers.

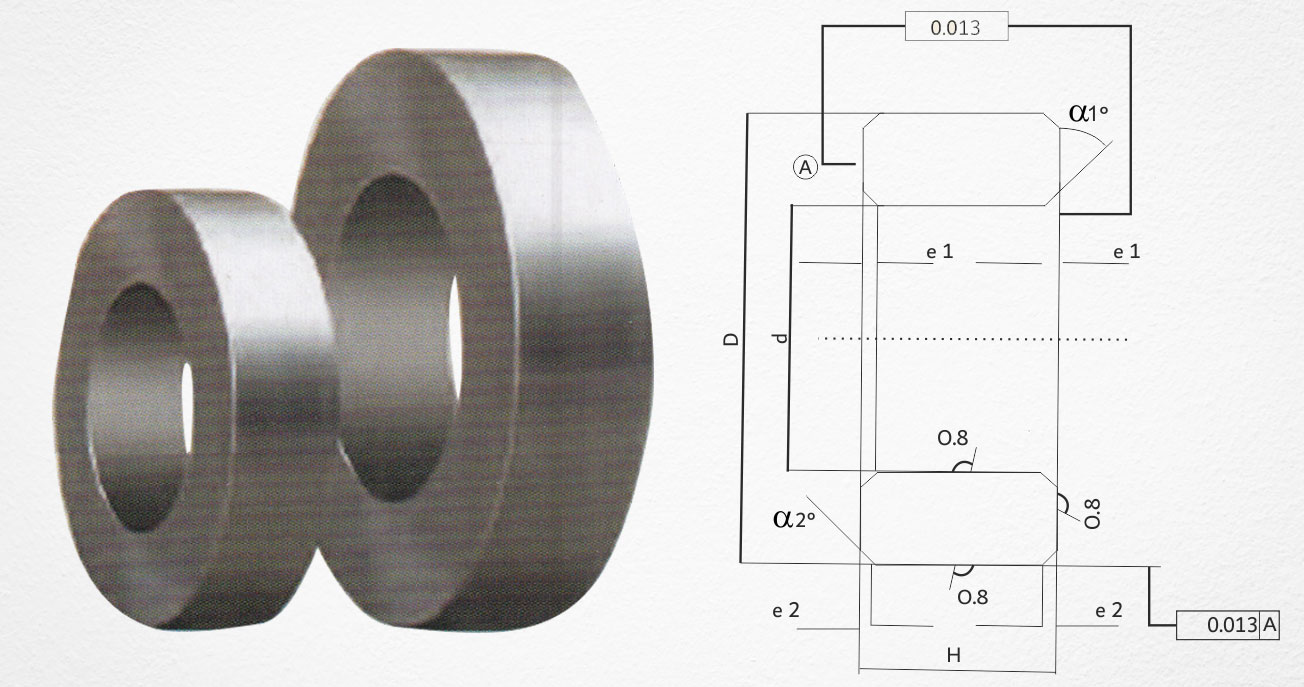

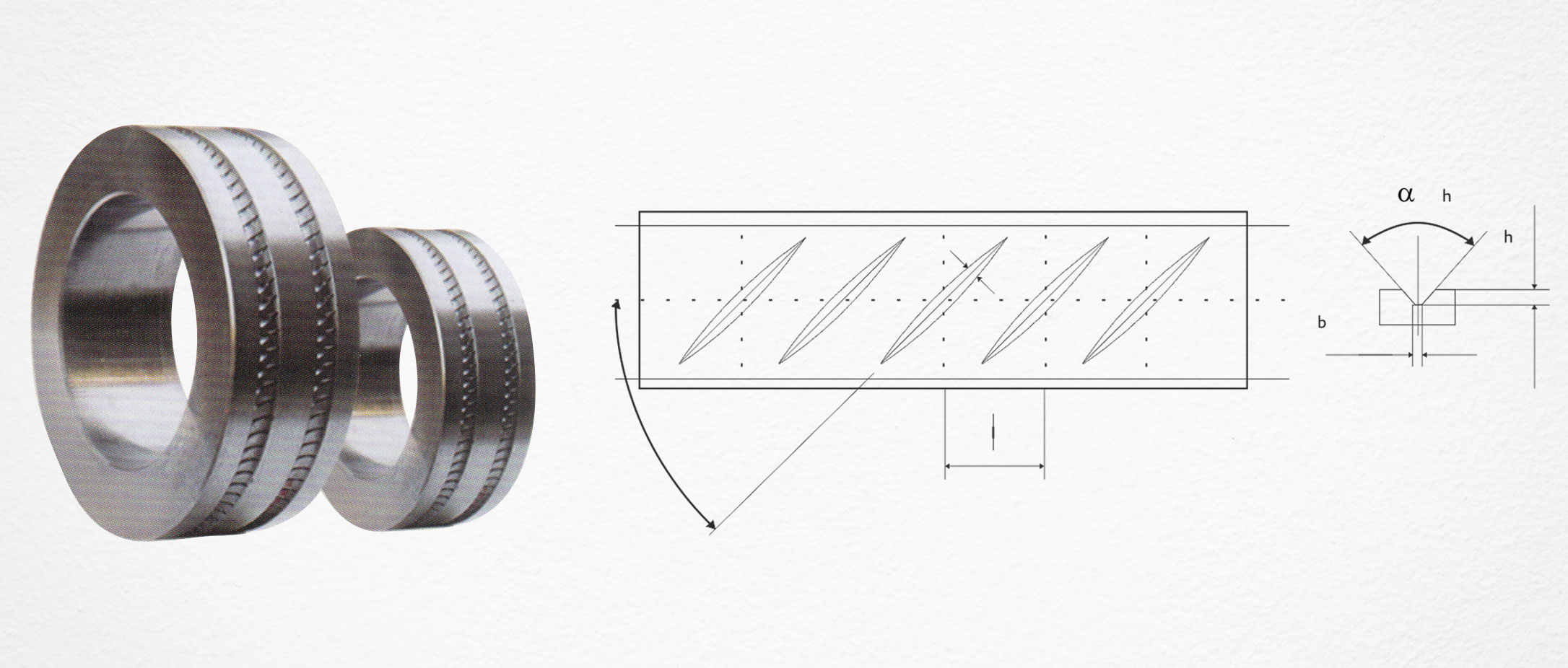

Radial Runout of Groove ≤ 0.013mm

Radial Runout of Groove ≤ 0.013mm Radial Runout of Periphery ≤ 0.013mm

Radial Runout of Periphery ≤ 0.013mm End Face Runout ≤ 0.02mm

End Face Runout ≤ 0.02mm End Face Planeness≤ 0.01mm

End Face Planeness≤ 0.01mm End Face parallelism ≤ 0.01mm

End Face parallelism ≤ 0.01mm Inner Hole Cylindericity ≤ 0.01mm

Inner Hole Cylindericity ≤ 0.01mm Inner Hole Roughness 0.4 µm

Inner Hole Roughness 0.4 µm Periphery Roughness 0.8 µm

Periphery Roughness 0.8 µm End Face Roughness 0.4 µm

End Face Roughness 0.4 µm

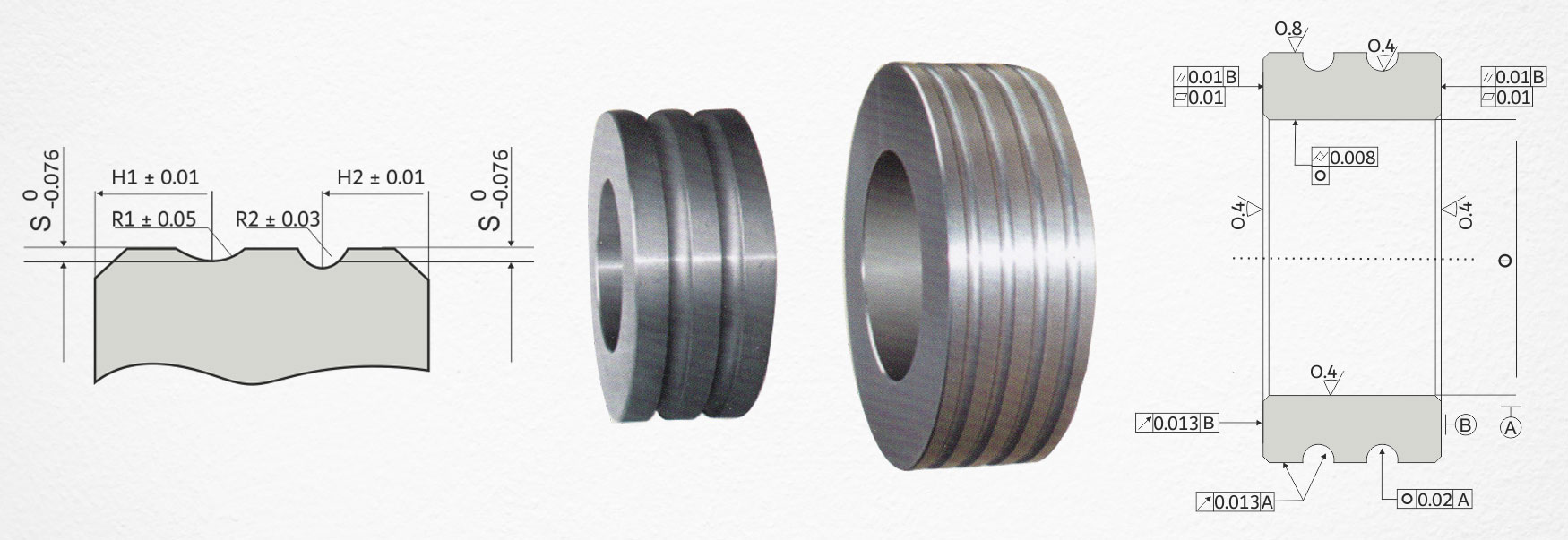

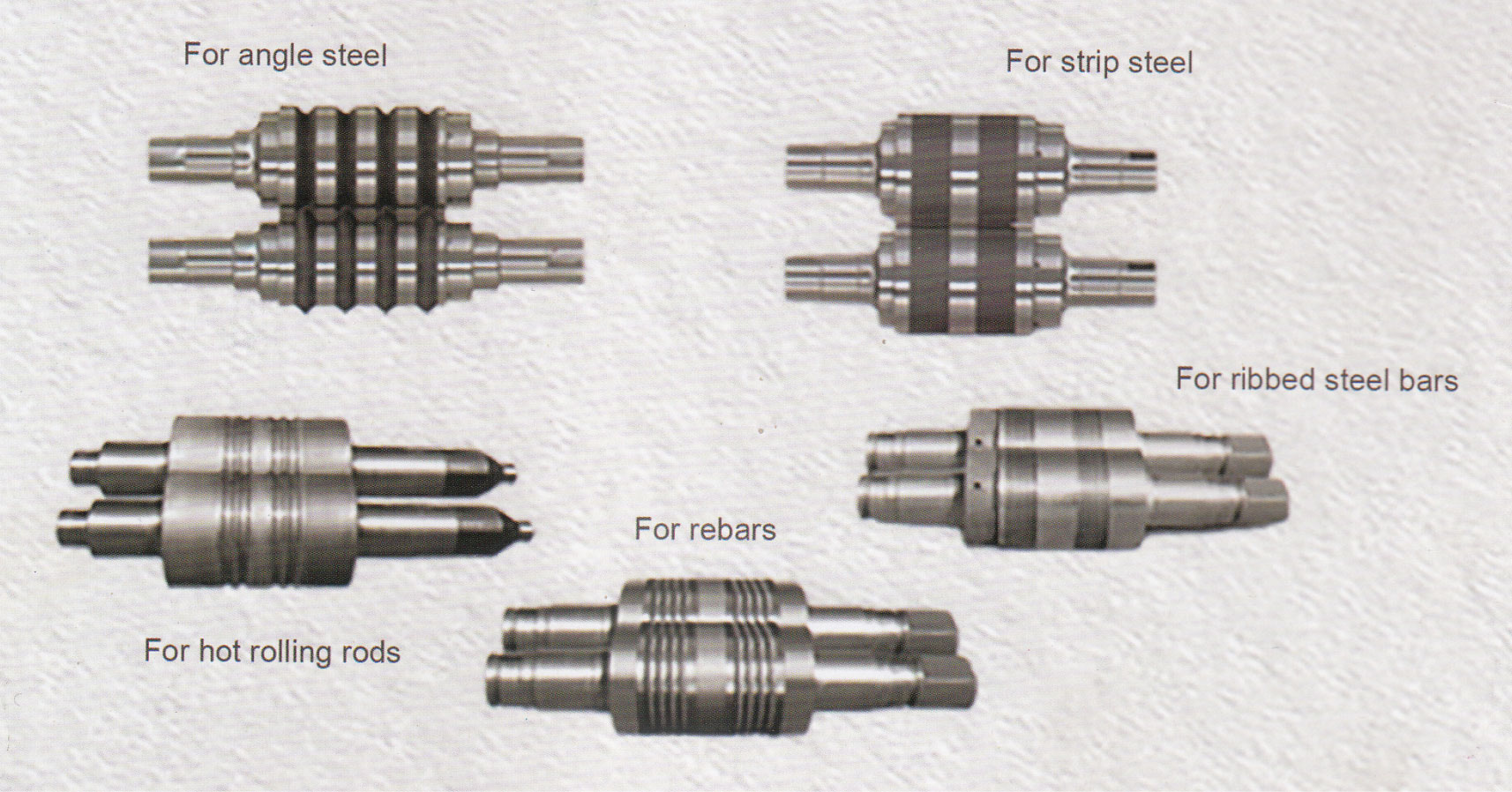

The Steel Reinforcement Rolled by Three Dimensional Carbide Rolls has Fine Appearance Surface High Precision In Dimension and Clear Ribbed Mark. Those Improved The Comprehensive Properties of Ribbed Steel Reinforcements. The Primary Rolling Tonnage are 600-2000 Tins, Which Is 20-30 Times More Than That of Common Tool Steel Rolls. Because Cemented Carbide Rolls Can be Reground and used again, The Production Cost is Reduced Greatly. That Markedly Improved Efficiency and Profit.

The Cemented Carbide Composite Rolls Mainly Used on The Finishing Mill to Bar, Deformed Steel Bar and Common Wire. In this Way, We Can Greatly Reduce the Frequency of Changing Groove and Roll, thus to Reduce the Labor Intensity and Improve The Work Efficiency. The Surface Quality and Yield Shall Be Improved to aMaximum Degree, Which Leads to a Adopts a Special Grade of Cemented. By Means of Hydraulic Lock Nut, The Cemented Carbide Roll Rings is Fastened to The Axle With The Axle Pressure Of 200 Mpa From Hydraulic Oil. Under The Protection of Prestress, The Cement Carbide Composite Roll Shall Work More Effectively.

| Grades | Chemical Composition | Physical Mechanical Properties | |||

|---|---|---|---|---|---|

| W | Co/Ni/Cr | Density ( ± 0.15) g/cm3 | Hardness ( ± 0.5) HRA | Bending Strength ≥ N/mm2 | |

| MG20F | 80 | 20 | 13.5 | 82.5 | 2650 |

| MG22F | 78 | 22 | 13.3 | 82.0 | 2600 |

| MG25F | 75 | 25 | 13.1 | 80.5 | 2550 |

| MG30F | 70 | 30 | 12.6 | 79.5 | 2450 |

| MG32F | 68 | 32 | 12.5 | 79.0 | 2400 |

Note: The allowable deviation in external diameter, internal diameter and height is to be determined based on customer's needs.

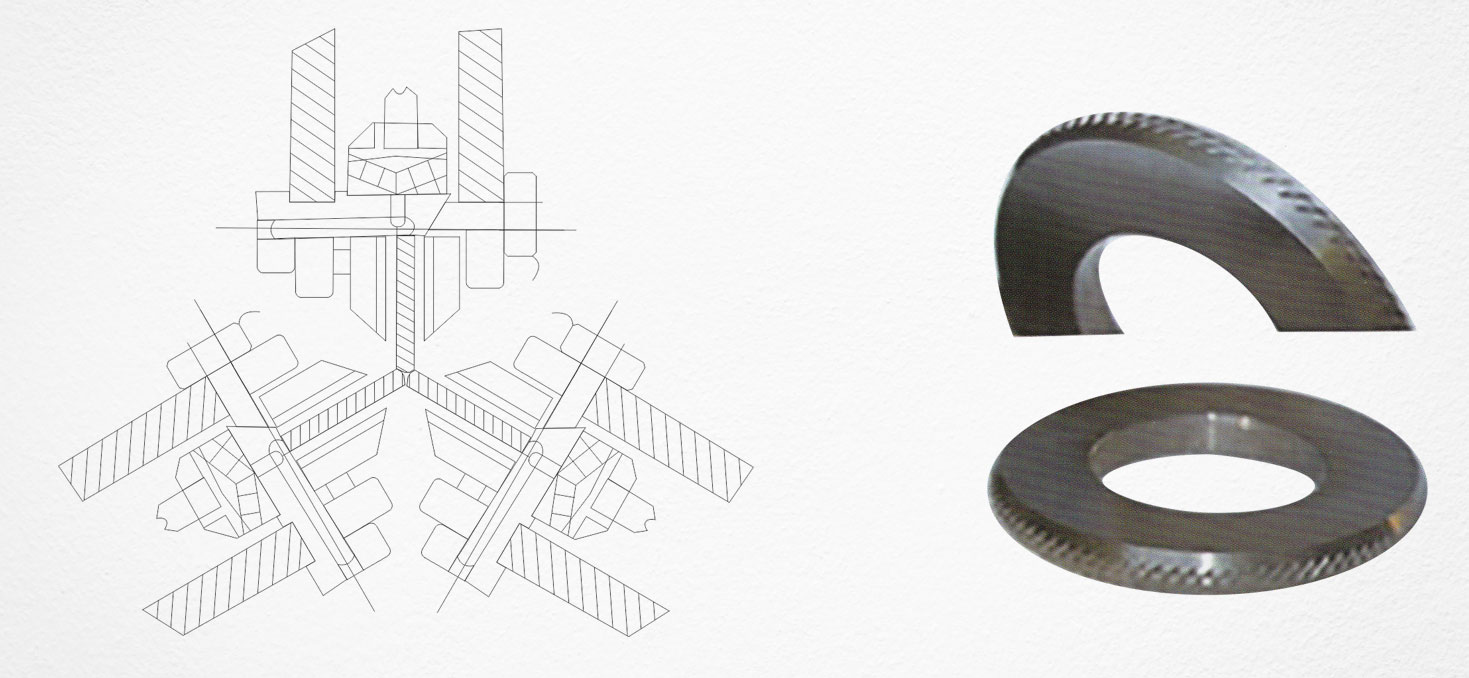

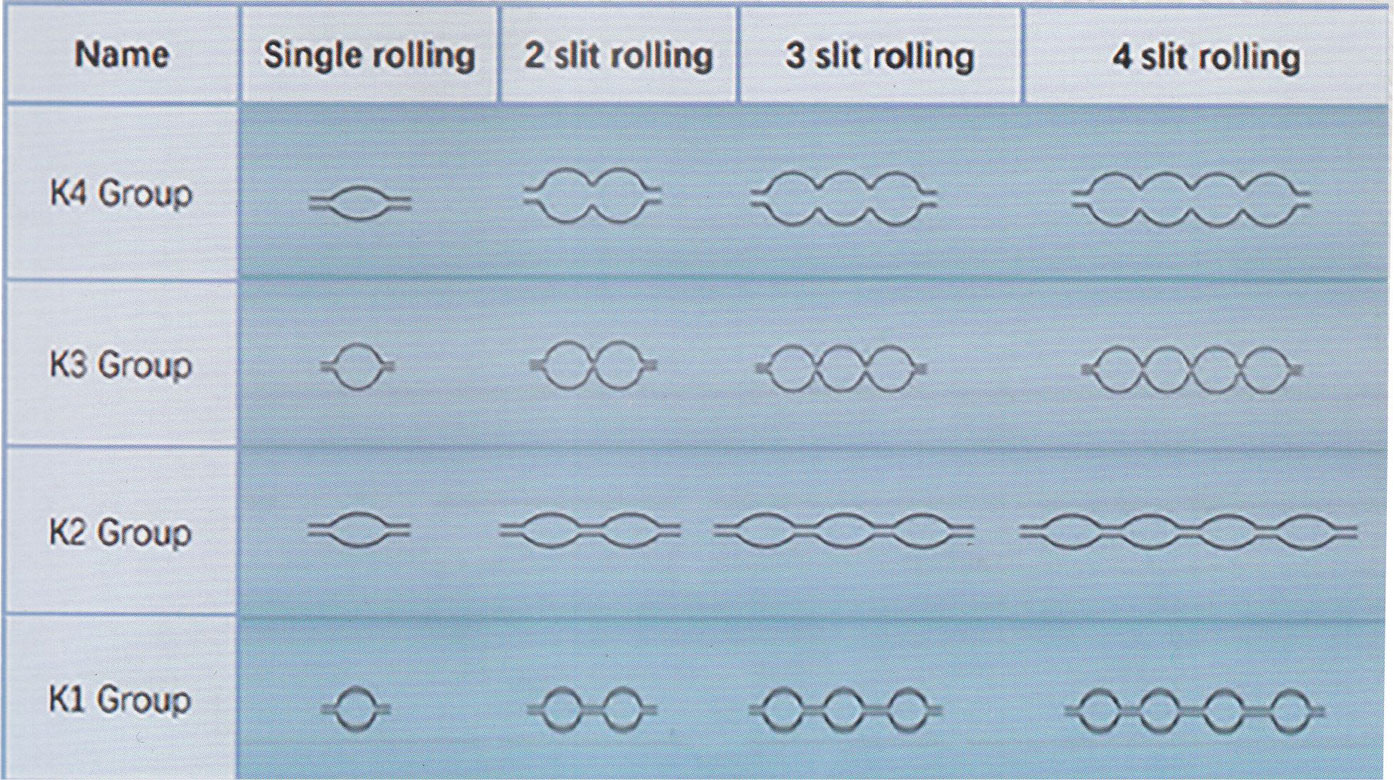

In accordance with the production line and rolling technology of customers, our products are designed to match one-strand rolling, two-slitting rolling and three-slitting rolling, and four slitting rolling, the cemented carbide composite roll includes K1 finished roller, K2 leder roller, K4 pre-slitting roller, K3 slitting roller with high-speed steel as material. the rolling varieties include wire, bar and deformed steel bar.

we can effectively reduce the frequency of changing rollers and increase the yield after using cemented carbide composite roll. The rolling products possess the features of good surface quality, small deformation, negative tolerance and high yield.

Specailist in HSS Rolls, Tungsteen Carbide Rings & All Types of Rolls.